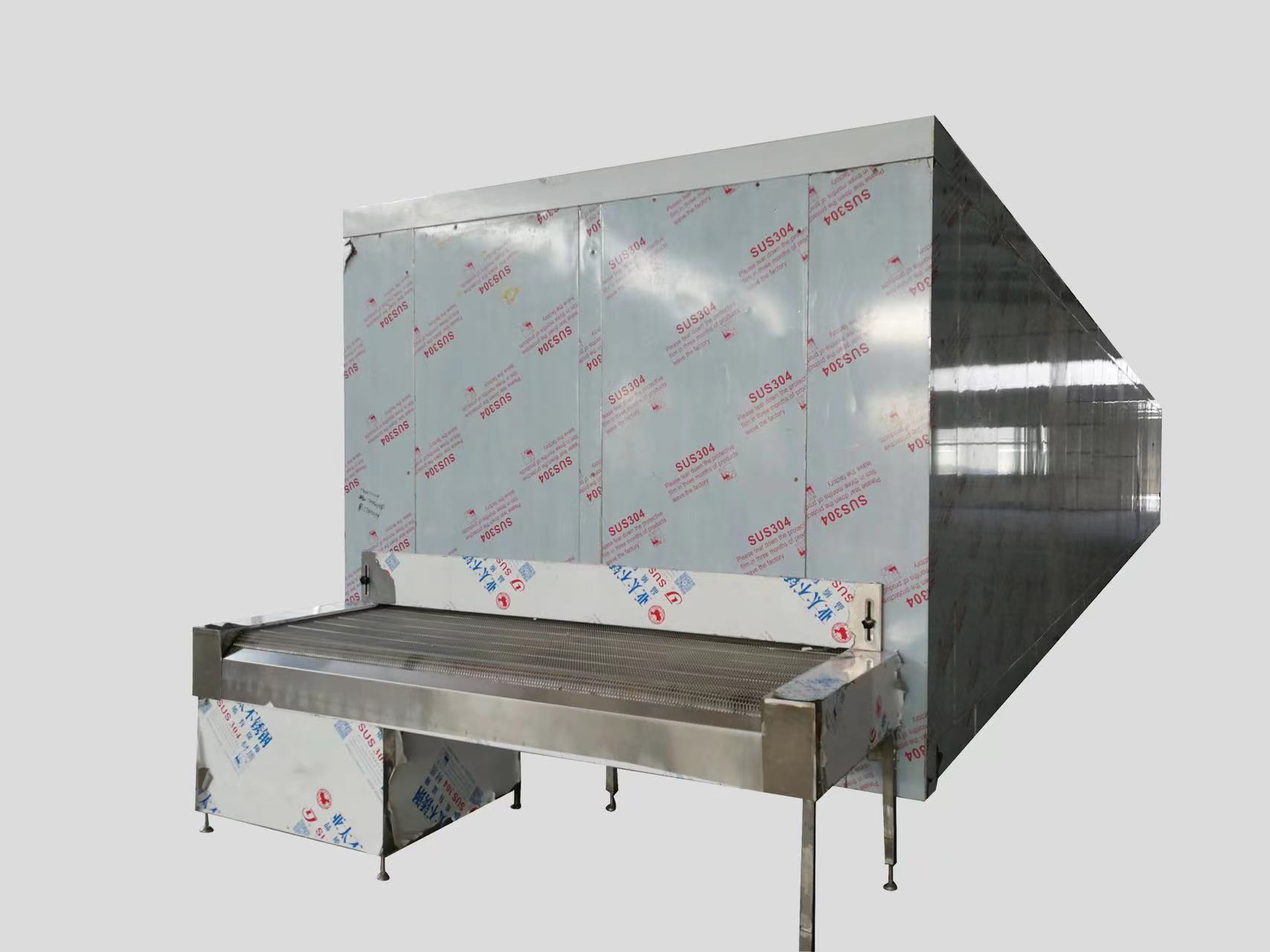

The overall structural characteristics and performance of the tunnel quick-freezer: Overall design 1. The whole equipment is designed and manufactured in compliance with HACCP and the new version of food and drug GMP, SC and other requirements; in line with the People's Republic of China "Food Monomer Quick Freezing Device" standards and commodity inspection export requirements. 2. The internal and external structures of the warehouse are all made of food-grade stainless steel SUS304, all of which are argon arc welding, and the weld joint is pickled. (Except for standard parts and special parts such as reducers and motors). 3. Design process structure parameters according to the characteristics of quick freezing of frozen products. The evaporator is designed with a large effective surface area; the large-pitch aluminum alloy finned tube group is adopted, and the variable-pitch design is adopted to reduce the temperature difference between the evaporator and the warehouse. The design selection is based on the evaporating temperature. -42 degrees Celsius calculation. Sufficient evaporation area, high heat exchange efficiency, full consideration of the influence of incoming and outgoing temperature, the design makes frosting lag behind, and prolongs the working time of the quick-freezer. 4. The evaporator is equipped with a high-efficiency, low-noise, waterproof, moisture-proof and low-temperature axial flow fan. 5. The temperature of the product is reduced to -18°C by using the temperature inside the warehouse at -35°C and the principle of tunnel side blowing and the frequency conversion conveyor belt. 6. The organic combination of evaporator, fan, air guide device and vibration device forms a uniform and stable frozen product suspension and a negative feedback fluidized bed with multi-directional monomer wind, which makes the frozen product monomer freeze more quickly and quality Unite; 7. The external centralized water valve is used to control the uniform water frosting to prevent bacteria from multiplying, clean and hygienic, and meet the food hygiene requirements. The evaporator in the quick-freezing room is equipped with an integrally welded stainless steel large water tray; the warehouse body is equipped with an overhaul door with electric heating, and all corners of the quick-freezing machine are easy to clean and maintain; except for the slow running of the mesh belt, other transmission devices are in the heat preservation cover, and the cover is easy Disassembly and assembly; an emergency stop safety button and safety warning signs are set; the quick-freezing machine is equipped with an adjustable device that moves up and down horizontally. 8. The feed inlet is equipped with an adjustable wind-shielding and heat-preservation device with an adjustable height limit to uniformly distribute the product and avoid the loss of cold energy. The air guide adjusting device can adjust the wind direction and control the uniformity of the cold air; 9. The stainless steel SUS304 conveyor belt chain adopts a 38.1mm double-pitch large roller chain for rolling transmission to avoid deformation and breakage of the chain; 10. The return belt of the mesh belt conveyor is in the warehouse. The five sides of the incoming bar are insulated. An adjustable stainless steel wind shield is attached to the cargo port. The six sides of the outgoing bar are insulated, which can realize automatic blanking and keep the mesh belt conveyed at low temperature. Operation, with pre-cooling effect. 11. Adopt full-length stainless steel sidewalls, and the frozen products are relatively closed inside the transmission tunnel, preventing the frozen products from turning over and blowing out of the tunnel. 12. High-quality cycloid pinwheel reducer and frequency converter realize stepless speed regulation of mesh belt transmission. The quick freezing time can be adjusted arbitrarily. 13. Adequate storage surface area, effective use of refrigeration capacity, suitable for quick-freezing processing of different frozen products, high efficiency and energy saving.

简体中文

简体中文 English

English